ROCK.ZONE Hydraulic Attachments

DCS Techno Services is an authorized dealer of ROCK.ZONE, supplying high-performance hydraulic attachments for excavation, demolition, screening, and crushing applications.

Why ROCK.ZONE?

- Heavy-duty hydraulic attachments

- Designed for demanding site conditions

- High productivity & on-site processing

- Reduced material handling & transport

- Proven performance across applications

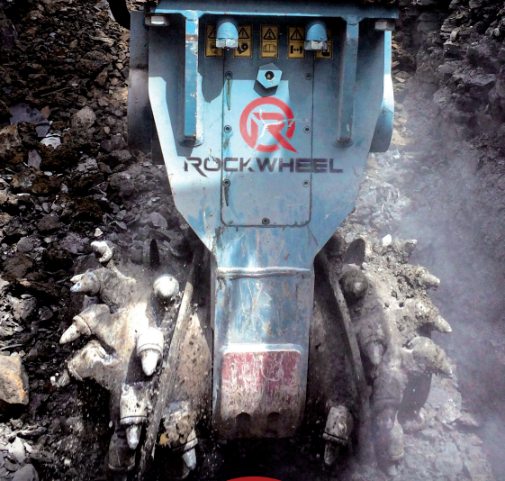

Rockwheel – Drum Cutters

Hydraulic drum cutters for cutting, trenching, profiling, and demolition.

Rock screener – Screening Buckets

High-capacity screening buckets for on-site material processing.

Rock crusher – Crusher Buckets

Crusher buckets for on-site crushing and reuse of material.