Kennametal Mining Solutions

Advanced Tooling | Wear Protection | Mining Performance

With 85+ years of expertise, Kennametal delivers reliable mining tooling and wear-resistant solutions designed for tough operating conditions. Its mining tools for excavation are built to perform consistently in demanding mining environments. DCS Techno Services, as an authorized distributor, supplies the complete Kennametal portfolio to mining operations across India.

Mining Applications

- Underground Mining

- Surface Mining

- KenCast Wear Protection

Explore Kennametal Mining Categories

Underground Mining

- Conicals

- Crushers

- Radials

- Cutting systems

- Roof bits

- Drilling systems

- Continuous miner tools

- Accessories

Surface Mining

- Conicals

- Compacts

Wear Protection

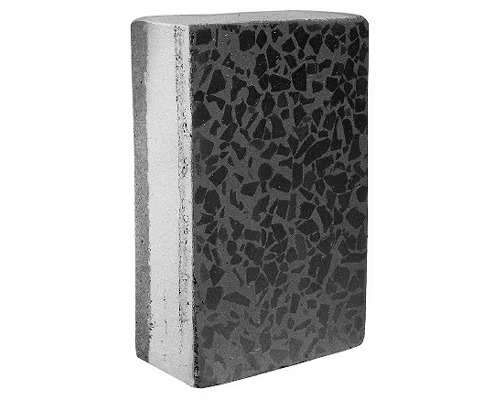

- KenCast wear protection

- KenCast excavator buckets

- Carbide-tipped Bits & Picks — for high penetration, minimal breakage, efficient rock fragmentation.

- Complete Cutting Systems & Drums — for surface miners, shovels, haul trucks, crushers.

- Compacts & Components — engineered compacts designed for heavy-duty excavation and rock removal tasks.

- Wear Protection (KenCast™ and Wear Parts) — wear-resistant components for rock-handling surfaces, rock chutes, conveyors, dumpers, crushers, etc.

Best for: Open-pit mines, quarries, haul-truck operations, shovel-excavation, bulk rock removal

- Conical Picks / Bits, Block & Drum Systems — for continuous miners, road-headers, longwall shearers, feeder-breakers.

- Crusher Picks & Bits (various shank sizes: 38 mm / 51 mm / 52 mm etc.) — built to endure high-impact & abrasive crushing underground.

- Drilling Systems & Roof-Bolting Tools — for support drilling, shaft drilling, borehole drilling in underground operations.

- Wear Protection Components — liners, wear plates, wear-resistant parts for feeders, conveyors, crushers, material handling under harsh conditions.

Ideal for: Coal mines, ore mines, hard-rock tunnels, longwall operations, underground crushers & conveyors

- High-Pressure Grinding Rollers (HPGR) Components — carbide components, liners, wear-resistant parts for mineral processing and comminution circuits.

- Custom Wear Parts & Claddings — for chutes, material handling systems, high abrasion zones — to extend service life and reduce downtime.

Why Kennametal Mining Tools via DCS Techno Services?

- Global-grade carbide tooling & wear parts — proven under extreme mining conditions worldwide.

- Comprehensive range — from surface mining to underground, from drilling to crushing to wear-protection.

- Maximized equipment uptime & lower cost per ton — thanks to long tool life, fewer changeouts, robust wear protection.

- Expert support in India — correct tool selection based on geology, application & equipment; genuine OEM parts; reliable supply via DCS Techno Services