Kennametal Mining Solutions

Advanced Tooling | Wear Protection | Mining Performance

With 85+ years of expertise, Kennametal delivers top-tier mining tooling and wear-resistant solutions engineered for severe mining conditions. DCS Techno Services — as authorized distributor — brings the full Kennametal portfolio to mining operations across India.

Mining Applications

- Underground Mining

- Surface Mining

- KenCast Wear Protection

Explore Kennametal Mining Categories

Underground Mining

- Conicals

- Crushers

- Radials

- Cutting systems

- Roof bits

- Drilling systems

- Continuous miner tools

- Accessories

Surface Mining

- Conicals

- Compacts

Wear Protection

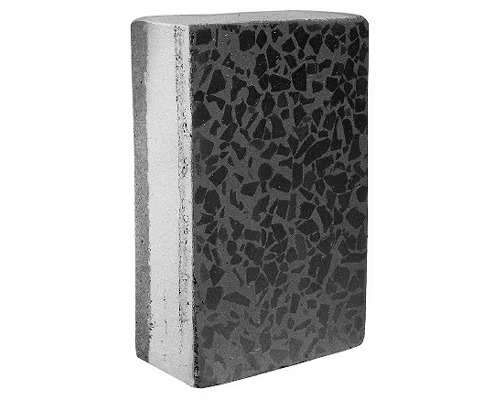

- KenCast wear protection

- KenCast excavator buckets

- Carbide-tipped Bits & Picks — for high penetration, minimal breakage, efficient rock fragmentation.

- Complete Cutting Systems & Drums — for surface miners, shovels, haul trucks, crushers.

- Compacts & Components — engineered compacts designed for heavy-duty excavation and rock removal tasks.

- Wear Protection (KenCast™ and Wear Parts) — wear-resistant components for rock-handling surfaces, rock chutes, conveyors, dumpers, crushers, etc.

Best for: Open-pit mines, quarries, haul-truck operations, shovel-excavation, bulk rock removal

- Conical Picks / Bits, Block & Drum Systems — for continuous miners, road-headers, longwall shearers, feeder-breakers.

- Crusher Picks & Bits (various shank sizes: 38 mm / 51 mm / 52 mm etc.) — built to endure high-impact & abrasive crushing underground.

- Drilling Systems & Roof-Bolting Tools — for support drilling, shaft drilling, borehole drilling in underground operations.

- Wear Protection Components — liners, wear plates, wear-resistant parts for feeders, conveyors, crushers, material handling under harsh conditions.

Ideal for: Coal mines, ore mines, hard-rock tunnels, longwall operations, underground crushers & conveyors

- High-Pressure Grinding Rollers (HPGR) Components — carbide components, liners, wear-resistant parts for mineral processing and comminution circuits.

- Custom Wear Parts & Claddings — for chutes, material handling systems, high abrasion zones — to extend service life and reduce downtime.

Why Kennametal Mining Tools via DCS Techno Services?

- Global-grade carbide tooling & wear parts — proven under extreme mining conditions worldwide.

- Comprehensive range — from surface mining to underground, from drilling to crushing to wear-protection.

- Maximized equipment uptime & lower cost per ton — thanks to long tool life, fewer changeouts, robust wear protection.

- Expert support in India — correct tool selection based on geology, application & equipment; genuine OEM parts; reliable supply via DCS Techno Services